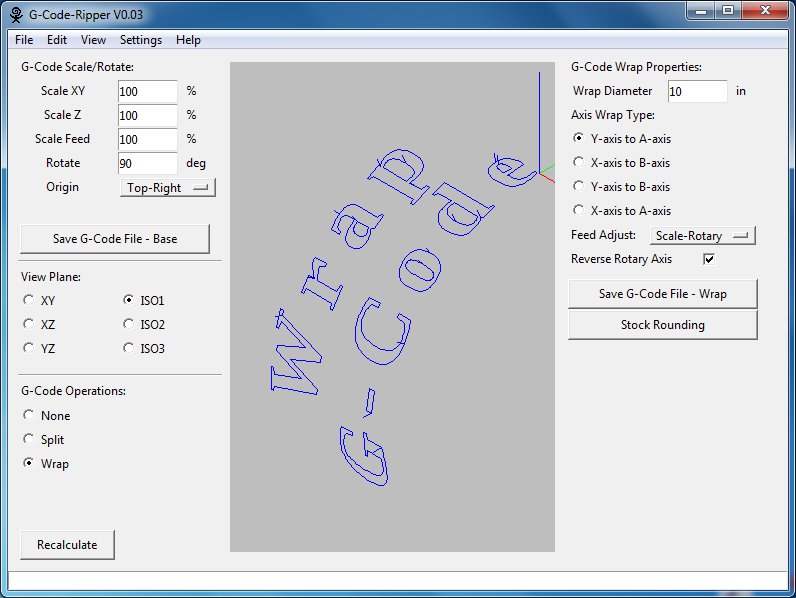

I recently released G-Code Ripper Version 0.23 which includes the ability to do basic backlash compensation on a g-code file. The new version van...

Category: CNC

Prism Shaped Name Plate for Kaitlyn

I made a three sided nameplate for my goddaughter Kaitlyn’s 1st birthday. The main body is basswood and “Kaitlyn” is inlayed on each side of the...

V-Carve Inlays and More with F-engrave 1.50

F-Engrave 1.50 has been released and is now available on the F-Engrave page. Here are a few of the highlights from this release: Modified...

Dmap2Gcode (image to g-code) Update

I released a new version of the image to g-code conversion program Dmap2Gcode. The new version is 0.02, the updates to the program are listed...

Auto Probing With G-Code Ripper

When g-code is generated by most software it is assumed that the stock material is flat and level. Sometimes the stock material is warped, not...

F-Engrave V1.32

F-Engrave Version 1.32 is now available on the F-Engrave Web Page. This release includes a few minor items that I have had backlogged for a...

F-Engrave V1.31 (Bug fix for batch mode)

I made a quick release of F-Engrave Version 1.31 to fix a new bug that was preventing batch mode from working in version 1.30. I have a backlog of...

My Entry for the Hackaday Logo Contest

Hackaday is having a contest to see where people can put the Hackaday skull and wrenches logo. I thought I would take a little time and throw...

G-Code Ripper 0.04 – Bug Fix

G-Code Ripper 0.04 has been released with a fix for a bug that can occur when reading arc segments (G3,G3). The new version also allows zero...

G-Code Wrapping with G-Code Ripper

G-Code Ripper version 0.03 has been posted to the G-Code Ripper Homepage. The new version has more plotting options including more isometric...

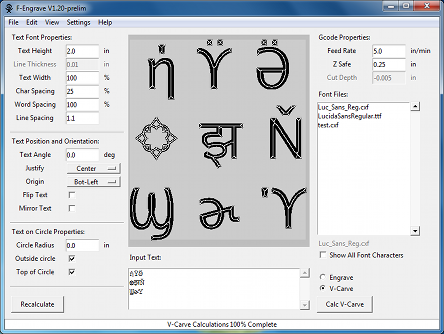

F-Engrave 1.20 With Extended Character Support

F-Engrave 1.20 with extended character support is now available for download. To enable extended characters in F-Engrave there is a new setting...

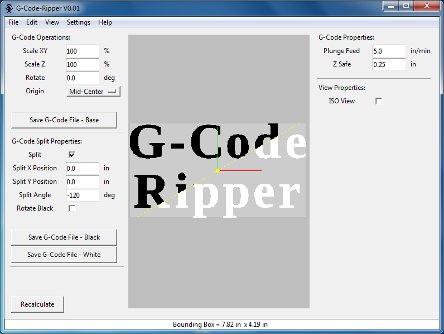

G-Code Ripper Released

I have uploaded the first version of G-Code Ripper (formerly referred to as the g-code splitting program). G-Code Ripper can read g-code files...

G-Code Splitting Progress

I have been making progress on the g-code splitting program (yet to be named). I think I have all of feature for the initial release, including...

G-Code Bending

Using the g-code interpreter that I am developing for the g-code splitting program I read some g-code generated by F-Engrave and mapped the...

G-Code Splitting Project

I am working on a new program (Python script) that can split an existing g-code file into two halves. This will allow users to take a file run half...