Composite Repair and Reinforcement

Sometimes a broken part was generally too weak to begin with or does not have much surface area for bonding. To achieve a good repair additional material needs to be added to supply more strength or surface area for bonding. One way that I have used to provide the additional material has been to wrap string around the parts and bond the assembly together into one solid mass. This is essentially a low tech composite material. The resulting repairs are very strong. The scissors in the picture above has taken much more abuse after the repair than it did before it initially broke. I regularly use the scissors to cut cardboard and whatever else gets in my way in my shop.

Embedded below is a video detailing this method being applied to the handles on a cheap dial indicator stand.

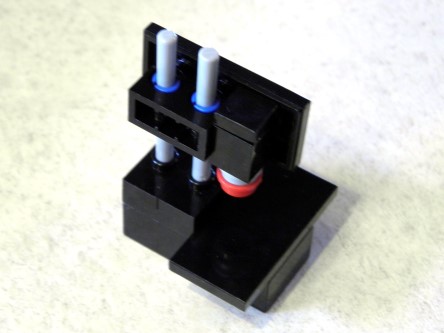

In addition to repairs this technique can be used to reinforce items that are likely to fail before they are put into service. The picture below shows a toy that I made for my kids (Lord Garmadon’s staff). The two pieces of wood are joined in such a way that the staff would likely split along the grain if not reinforced. For this item I used school glue and kite string.

The first time I ever saw this method used was in a model airplane. In the airplane there were push rods running from the servos to the control surfaces. The ends of the push rods were made from steel piano wire and the middle of the push rods were made from balsa wood. In order to secure the piano wire to the balsa the instructions detailed how to overlap the piano wire and balsa then wrap the overlapping region with string coated with glue. The procedure produced a very solid push rod assembly.

I have found this to be a reliable method to repair and join parts. I hope you find it useful too.