Newton’s Cradle

Over the Memorial Day weekend I made this newton’s cradle for my kids. I used some 5/8 inch ball bearings I had left over from another project. Instead of trying to drill into the bearings I choose to injection mold a plastic ring around the bearing. This allowed me to tie the strings to the injection molded plastic part rather than directly to the ball bearing. Below is a picture of one of the ball bearings with the ring molded around it (and the aluminum mold). The plastic was molded right onto the bearings inside the mold.

I used fishing line to tie the bearings to the frame. The fishing lines for each bearing are passed through a small holes in the top board and wrapped around a screw. Turning the screws on the top board adjusts the length of the strings to fine tuning the alignment of the bearings. Aligning the bearings is critical to getting good performance from the newton’s cradle.

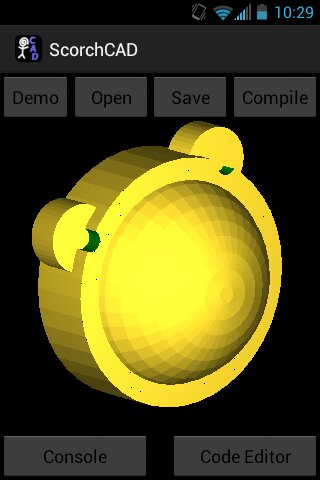

The injection molded collar for the bearings was designed on my Android phone using ScorchCAD while I was at one of my kids baseball practices. I exported and STL file for the mold from ScorchCAD and created the g-code file for my CNC mill using MeshCAM. So unless someone protests I am claiming I made the first physical part from a part designed from start to finish on a smart phone using ScorchCAD. A screenshot of the ScorchCAD part is shown below.