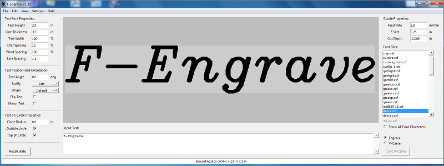

The latest version of F-Engrave includes major improvements to the v-carve calculation speed. The first is based on input from geo01005. He...

Author: Scorch

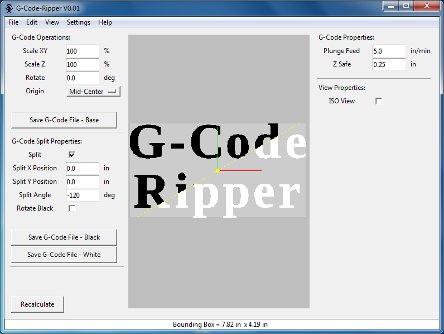

Auto Probing With G-Code Ripper

When g-code is generated by most software it is assumed that the stock material is flat and level. Sometimes the stock material is warped, not...

F-Engrave V1.37

I released a new version of F-Engrave with minor fix to better v-carve imported DXF files with small imperfections. F-Engrave V1.37.

Micro Foundry Progress – Crucibles

I have been sporadically experimenting with my electric micro foundry setup for almost a year. Recently I have been trying different...

Newton’s Cradle

Over the Memorial Day weekend I made this newton's cradle for my kids. I used some 5/8 inch ball bearings I had left over from another...

Hot Glue Injection Molding

I thought it would be interesting to see how well a simple hot glue gun with standard hot glue could produce injection molded parts. Although...

ScorchCAD Released on Google Play

ScorchCAD (A clone of OpenSCAD for Android devices) is now available on Google Play: ScorchCAD. There is also a new ScorchCAD webpage here:...

ScorchCad Preview (Update 2)

This is my second short update of my progress on ScorchCAD (A clone of OpenSCAD for Android devices). I am slowly adding more features and...

Using F-Engrave with GRBL (ShapeOko)

I have had some feedback from ShapeOko users indicating that there are some issues using the default F-Engrave output with GRBL. I thought I...

G-Code to DXF with G-Code Ripper

G-Code Ripper Version 0.05 is now available. The new version can export tool paths read from a g-code file to a DXF or CSV (Comma Separated...

ScorchCad Preview (Update 1)

This is a quick update of my progress on ScorchCAD (A clone of OpenSCAD for Android devices). I am slowly adding features. So far I these...

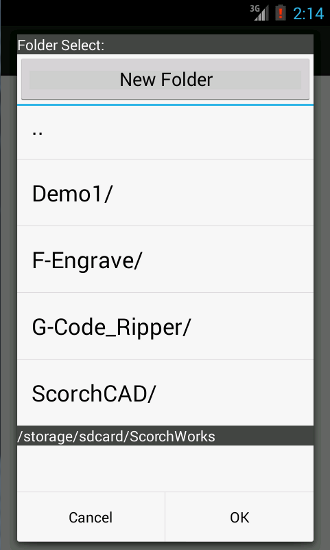

Simple File Dialog For Android Applications

Since there isn't a built in file dialog interface for android development I have been searching for one that I could use without starting from...

F-Engrave 1.33

I uploaded version 1.33 of F-Engrave, it is available on my web page. (F-Engrave 1.33) Changes in Version 1.33: - Added option for scaling...

Simon Hack a Day’ing

Hack a Day is having another contest. This time it is a microcontroller based contest. The entries need to hide hackaday.com in a...

F-Engrave V1.32

F-Engrave Version 1.32 is now available on the F-Engrave Web Page. This release includes a few minor items that I have had backlogged for a...

Composite Repair and Reinforcement

Sometimes a broken part was generally too weak to begin with or does not have much surface area for bonding. To achieve a good repair additional...

ScorchCAD Preview

ScorchCAD is a side project that I have worked on for a while. It is a clone of OpenSCAD written for Android devices. It is a clone of...

F-Engrave V1.31 (Bug fix for batch mode)

I made a quick release of F-Engrave Version 1.31 to fix a new bug that was preventing batch mode from working in version 1.30. I have a backlog of...

My Entry for the Hackaday Logo Contest

Hackaday is having a contest to see where people can put the Hackaday skull and wrenches logo. I thought I would take a little time and throw...

G-Code Ripper 0.04 – Bug Fix

G-Code Ripper 0.04 has been released with a fix for a bug that can occur when reading arc segments (G3,G3). The new version also allows zero...

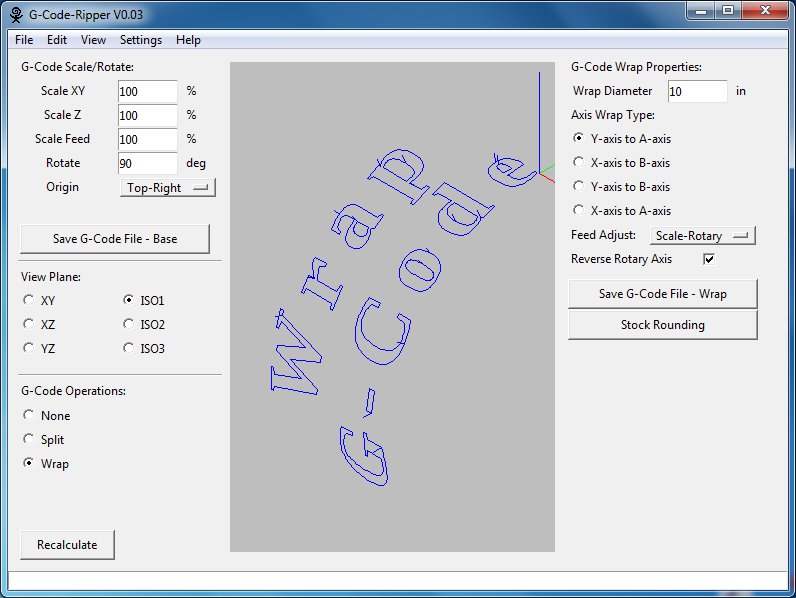

G-Code Wrapping with G-Code Ripper

G-Code Ripper version 0.03 has been posted to the G-Code Ripper Homepage. The new version has more plotting options including more isometric...

PVC Pipe Lithophane

I saw a video of a cylindrical lithophane made from a PVC pipe a few years back (You tube Link). I had always wanted to replicate it. Not only...

F-Engrave V1.30 (Auto Loop Flipping)

F-Engrave now can determine which side of the loops in a DXF design need to be cut. Previously the input needed to be formatted so that the...

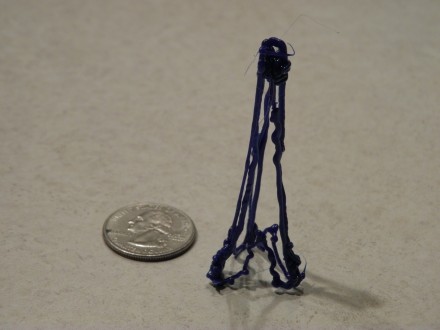

Playing with 3Doodler

I had a chance to sit down for a couple of minutes with a 3Doodler. In just a minute or two I made the little tripod tower in the picture. It...

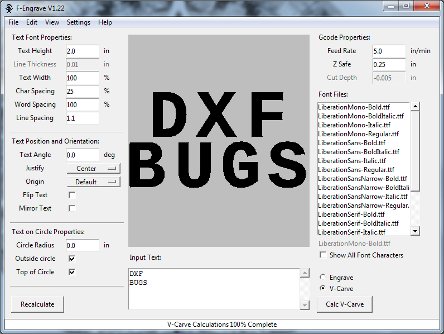

F-Engrave V1.22 (DXF Bugs)

F-Engrave V1.22 is now available. This version fixed a few DXF import bugs and a v-carve cleanup bug. I also changed the lower limit on the...

Tiny Aluminum Yoda

I have been working on making a very small electric furnace for doing small aluminum castings. As part of testing an early iteration of the...

F-Engrave Command Line Options

Version 1.21 of F-Engrave is now available. More command line options have been added. A new batch mode (-b,--batch) that skips the GUI. ...

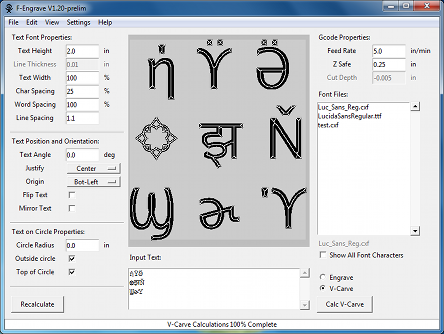

F-Engrave 1.20 With Extended Character Support

F-Engrave 1.20 with extended character support is now available for download. To enable extended characters in F-Engrave there is a new setting...

G-Code Ripper Released

I have uploaded the first version of G-Code Ripper (formerly referred to as the g-code splitting program). G-Code Ripper can read g-code files...

G-Code Splitting Progress

I have been making progress on the g-code splitting program (yet to be named). I think I have all of feature for the initial release, including...